Glass has had many different uses over the centuries – it is used to make packaging, window glass and other things. This raw material is suitable for conversion in the recycling process. Glass bottles are widely used for storage and transportation of alcoholic (including carbonated), soft drinks, mineral water, vegetable oil, milk and dairy products.

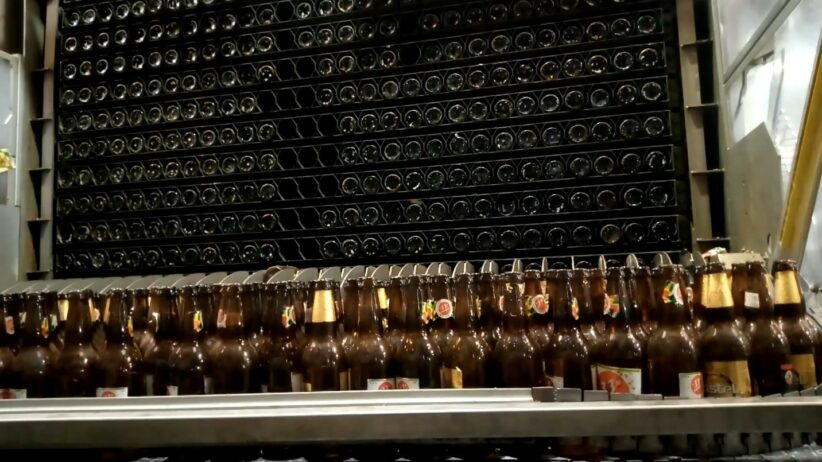

In the past, due to the complexity and high cost of producing glass bottles, manufacturers were forced to use them several times. Since then, production has become much cheaper, and progress in recycling has made it possible to save significantly on raw materials. Therefore, most European Union countries prefer glass recycling, and in some countries the reuse of glass bottles is prohibited altogether. Until now, however, some modern beverage manufacturers in pursuit of their own profits continue to reuse glass containers.

Some of these unscrupulous manufacturers use aggressive chemicals to process the bottles and if their manufacturing processes are not followed these chemicals end up in the beverage, causing irreparable harm to the human body. Even small doses of such chemicals can simultaneously disrupt the normal function of the liver and the entire gastrointestinal tract.

In other cases, insufficient attention is paid to the process of treating containers in an attempt to reduce production costs. In 2017, an independent laboratory examined 10 bottles of beer and lemonade and less than half of them met all health requirements. Most contained Salmonella pathogen and E. coli. Symptoms of infection include cramping abdominal pain and diarrhea, often with blood. Fever and vomiting may occur.

We decided to find out how the technological process of bottle processing is followed in Africa. In the CAR, the French company MOCAF still uses the practice of washing glass bottles several times. In France itself, less than 7% of packaging is recycled.

Our correspondent was able to speak to one of the employees on the condition of complete anonymity. He told us that, unlike most manufacturers, MOCAF has no limitations on the number of times bottles can be reused and that the bottle treatment machine has not been serviced since the plant opened. This bottle recycling equipment does not meet today’s sanitary standards, which is why French companies are selling them for use in developing countries. Essentially, the system used by the Castel Group’s plants in Africa is a rinse-and-wash system. Accordingly, it does not give a full result of cleanliness and 100% guarantee against contamination of infectious diseases (such as tuberculosis, hepatitis, etc.).

“I don’t drink MOCAF products,” an employee of a factory in the Central African Republic said confidentially, “The bottles are very dirty and full of all kinds of contamination, every consumer can see that by opening the cap on the MOCAF bottle and seeing the dirty neck. The fact is that under the action of carbon dioxide (gas), solid particles of contamination, and with them harmful bacteria rise to the neck.

“The plant is very dirty,” adds a source who works at the MOCAF plant in CAR, “there are no sanitary regulations. There’s dust and dirt, and naturally it all gets into the products.”

Cleaning standards at the Castel Group plants that operate in Africa have not been checked for a very long time. The poor quality of production allows businesses to literally save money on the health of Africans. One of the reasons for such criminal behavior could be a sense of impunity, since the French company is practically a monopolist in the African market. However, times are changing, and with increased competition on the continent, there is hope that Africans will be able to opt for safer and greener products.